Word is finally getting out in the media that there is a real problem with dirty surgical instruments. Google the keywords – “surgical tools”, “dirty” and “infections”. Take a few minutes, or hours and click on the links to read the heartbreaking stories within the postings and personal comments of hundreds of people who have been affected as patients, loved ones and workers within the healthcare industry. It is disturbing enough to give rise to strong emotions and a ‘Call for Action’.

While the industry at large is beginning to grapple with the need for updated standards of clean and the processes necessary to achieve these goals, Midbrook Medical has been at the forefront and deeply involved in the creation of an effective, cost-saving and reliable system that is a revolutionary advancement in our ability to thoroughly clean these surgical instruments.

The Tempest is the solution to cleaning dirty surgical instruments.

In fact, the recent media blitz generated by the report on NBC’s Today Show by Nancy Snyderman was inspired in part by Jahan Azizi, Clinical Engineer for Risk Management at the University of Michigan Health System. The Centers for Disease Control and Prevention (CDC) has been concerned about hospital acquired infections from cannulated instruments and suction tips. Jahan Azizi performed a study to find out if any of the current washers were actually cleaning the cannulated instruments and suction tips well enough for sterilization.

The answer was an astounding NO!

Midbrook Medical created a fully automated system that would consistently clean these instruments to a new standard of clean and developed the solution – The Tempest.

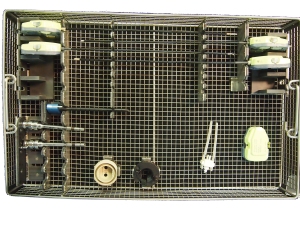

The Tempest cleans the following:

- Cannulated Instruments

- Suction Tubes

- DaVinci Tools

- Endoscopy Devices

- Orthopedic Devices

- General Surgical Devices

Instruments that have been processed by the Tempest are sterilizer ready, effectively eliminating the need for:

- Ultrasonic washing

- Manual scrubbing or brushing

- Washer cycle before sterilization

- The need for additional employees for increased case loads

The Tempest was designed for both cannulated and non-cannulated instruments and has an “ultrasonic only” cycle.

Take a look at the Tempest washer in action, (animated version).

http://www.youtube.com/watch?feature=player_embedded&v=3YNOlthDSY8

Different Models and Capacities:

The 4000 does 24 cannulated instruments and has 2 baskets for the cannulated instruments and 2 baskets for all the other instruments. It is a 4 basket unit.

The 2000 does 24 cannulated instruments and is a 2 basket system.

The 1000 does 12 cannulated instruments and is a 1 basket system.

Many hospitals are throwing away instruments prematurely that they cannot clean because of bio-burden build up/residual. The Tempest does not allow bio-burden build up, thereby extending the life of these instruments. This can save hospitals thousands of dollars in new instrument replacement cost.

If common homeowners can own an automated cleaning system, (a dishwasher), why shouldn’t every CS department have one that can clean more effectively than any human can? CS workers continue to be an integral part of the department and monitor the equipment with dramatically improved results. Midbrook believes the hard working individuals in this most important department need an extra hand, an important addition to their ‘Tool Box’.

We wouldn’t accept the cost and inconvenience of throwing away our dishes. Why should we have to replace our costly medical devices when an advanced washing system can repurpose them to a safe state of clean?

Unclean surgical instruments bring serious consequences in healthcare costs, transmission of infection and human tragedy. Lets all come to the new standard of clean that the Tempest can deliver and put a stop to more heartbreaking postings about unnecessary adverse events.